Contact support

Structural Industry Trends: Surge in Demand for Steel Pipes and Tubes

The Silent Skeletons of Modern Marvels

Years ago in the steel world, pipes and tubes were the stagehands supporting walls, backing up against concrete, and doing their job behind the scenes. They were the tough, quiet ones which are necessary, but invisible.

Then things changed.

Architects started dreaming bigger. Cities started going higher. Contractors looked for materials not only strong and safe but sleek, sustainable, and smart. And in this new engineering era, steel pipes and steel tubes took center stage. They emerged as visible skeletons of contemporary wonders, from floating skybridges to arcing metro lines.

This is not a tale of steel, it is a design revolution, where durability gets dressed up in style, and each pipe and tube have a story to tell about innovation.

Welcome to the era in which steel pipes and tubes no longer merely hold up buildings, they define the skyline.

The Backbone Reimagined: Pipes & Tubes in the Spotlight

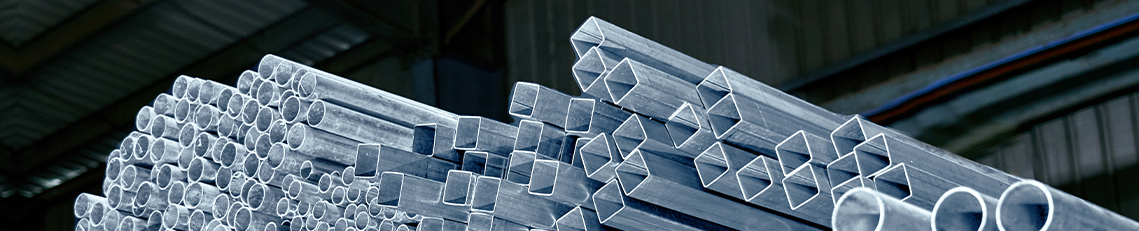

The structural sector is going through a dramatic change, fuelled by an increasing demand for steel tubes and pipes in architectural and infrastructural developments. No longer restricted to plumbing or small framework applications, structural-quality pipes and tubes are now the focal point of contemporary design.

Strength and Structural Safety

The use of hollow sections, including rectangular and square tubes, is a key to providing high structural strength while keeping total deadload remarkably low. As per a market analysis in the Indian Steel Market Outlook - FY 2024, the consumption of Hollow Structural Sections (HSS) increased by 18% in India, with high demand coming from commercial real estate and urban infrastructure development.

In addition, research by the Department of Civil Engineering (2023), Indian Institute of Technology (IIT) Madras, points out that hollow blocks made by pipes and tubes improve seismic performance as stress is shared evenly, minimizing the chance of structural collapse during earthquakes. This supports recent BIS (Bureau of Indian Standards) IS 800:2022 updates, which promote the application of light, ductile sections in seismic areas for enhanced security and conformity.

Understanding the Types of Steel Pipes in Construction

Steel pipes play an important role in construction and structural work as they give strength, support, and flexibility in design. Two common types of pipes are ERW (Electric Resistance Welded) pipes and CDW (Cold Drawn Welded) pipes. Both of these pipes are produced differently and are selected according to the project's requirements.

ERW pipes are used extensively because they are cost-effective and offer a uniform wall thickness. These MS pipes are suited for massive structures like bridges, malls, and stadiums, where reliability and strength matter the most.

CDW pipes, however, provide greater dimensional accuracy along with a smoother surface finish, making them suitable for architectural features that demand strength and precision. These technologies enable mass customization, accelerated production, and minimized wastage. These pipes are used in railings, frames, automative industry, furniture manufacturing, and industrial machinery.

Boosting Performance with Direct Forming Technology

Direct Forming Technology (DFT) is greatly enhancing the application of tubes and pipes in the structural market. DFT is making it possible to directly manufacture square, rectangular, and special-profile shapes from flat strips, eliminating the conventional round-forming process. These yields improved material efficiency, tighter tolerances, improved structural performance, and reduced costs of production. DFT also permits fast profile changes, enabling increased design flexibility and customization. With less waste, quicker production, and better sustainability, DFT structural tubes become cost-effective and performance capable. Hence their uptake in contemporary construction and infrastructure development is increased.

Aesthetics as a Design Driver

Modern building design combines how things look and how they work in new and creative ways. Sleek MS tubes and pipes enable architects to play around with futuristic and minimalist designs. Whether used for pergolas, mezzanine floors, or outside staircases, tubes make it possible to obtain sleek lines without the bulk of conventional materials.

The blending of aesthetic and structural purposes has turned steel tubes into a go-to option in luxury homes, shopping malls, and even institutional buildings.

“We’ve seen a definitive shift in structural design philosophies. More developers now prefer hollow sections due to their combination of strength, aesthetics, and eco- performance.”

- Neeraj Bansal, Structural Engineer & Consultant

2024 Steel Pipe & Tube Usage: At a Glance

According to Annual Market Trends Report, FY 2024, Ministry of Steel, the market for structural steel pipes in India reached a level of 3.6 million metric tons in FY 2024, a 22% increase from FY 2023.

According to Economic Times Infrastructure Review, Q1 2024, Indian metro rail projects utilized more than 0.8 million metric tons of steel pipes and tubes during FY 2024. The increase is primarily due to the increased use of ready-to-assemble components such as prefab sections and modular bridges to construct quickly and more efficiently.

As per Prefabrication & Modular Building Report 2024 by KPMG India, India is experiencing a large increase in prefab construction, by 10.5% annually. Steel pipes and tubes are the core of these structures, making it possible for builders to complete projects more quickly and securely, be it a home, a shopping mall, or a factory.

“In metro infrastructure and prefab systems, pipes and tubes are no longer an alternative - they're the default.”

- Rajeev Batra, Director, Batra Fabricators Pvt. Ltd.

Why Steel Pipes and Tubes Are Key to Today’s Structural Industry Growth

The structural industry has seen a rise in steel pipes and tubes in recent years because of growing needs from various sectors like construction, automotive, and oil & gas. As the majority of the population are living in cities, more buildings are needed in urban areas. Steel pipes and tubes fit the modern demands of construction due to their durability, toughness and low weight.

Steel pipes can handle high loads, resist rust and need little upkeep. Compared to other materials, steel pipes can save a lot of money in the future. Since they are so adaptable, they are useful in anything from large structural beams and columns to scaffolding and plumbing systems.

Recent demand for sustainability and investments in infrastructure has pushed up the popularity of both steel pipes and tubes. Since many industries consider steel to be both recyclable and eco-friendly, they prefer using it. While steel is both recyclable and eco-friendly, the form in which it is primarily used greatly influences its penetration. Hollow forms of metal, such as pipes and tubes, seem to be the most rewarding, due to their structure, aesthetics, and cost-related benefits.

Building the Future, One Smart Click at a Time

As the structural sector embraces smarter, faster, and more modular construction practices, Hashtagsteel is reshaping the steel supply chain. The platform is built for today’s dynamic project requirements. With construction speed and digitalization now going hand in hand, Hashtagsteel is driving the next evolution in structural development - one smart click at a time.

By @Shivani Hariharan on Saturday, 24 May 2025